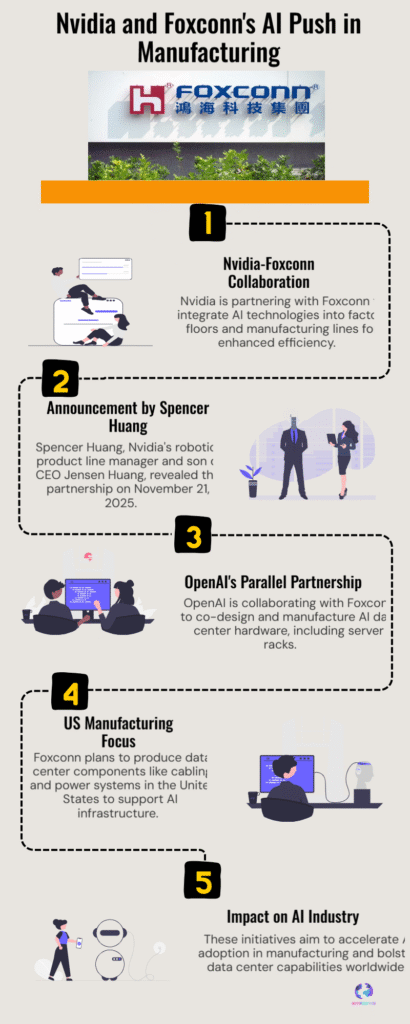

Nvidia and Foxconn are rewriting manufacturing rules. Learn how Omniverse digital twins, Isaac robotics, and AI servers are powering the global transition to self-optimizing smart factories.

Nvidia Foxconn partnership digital twin smart factory revolution

The strategic partnership between technology behemoth Nvidia and manufacturing giant Foxconn is not merely an upgrade; it signals the definitive start of the AI industrial revolution. Moving far beyond incremental efficiency gains, the Nvidia Foxconn partnership digital twin smart factory revolution is transforming traditional production lines into self-optimizing, intelligent ecosystems. This collaboration is fundamentally reshaping how everything, from next-generation AI servers to intelligent Electric Vehicles (EVs), is designed, built, and deployed globally.

At the core of this transformation is the advanced use of digital twin technology. Foxconn is leveraging the Nvidia Omniverse platform to create physically accurate, real-time simulations of its entire production facilities. This virtual-world testing allows engineers to plan new lines, simulate automated processes, and optimize layouts before a single physical component is moved.

The foundation for this intelligence is the creation of specialized AI factories—high-performance data centers built by Foxconn utilizing Nvidia’s most powerful GPU computing infrastructure, including the GB200 and Blackwell platforms. These AI factories serve as the engines that process the massive volumes of data collected from the automated manufacturing lines. The resulting insights power everything from quality control and bottleneck analysis to training the AI models necessary for the generative AI applications of tomorrow. This infrastructure is not only crucial for Foxconn’s operations but is also being offered as cloud services, positioning Foxconn as a key provider of high-density AI workloads to other global enterprises.