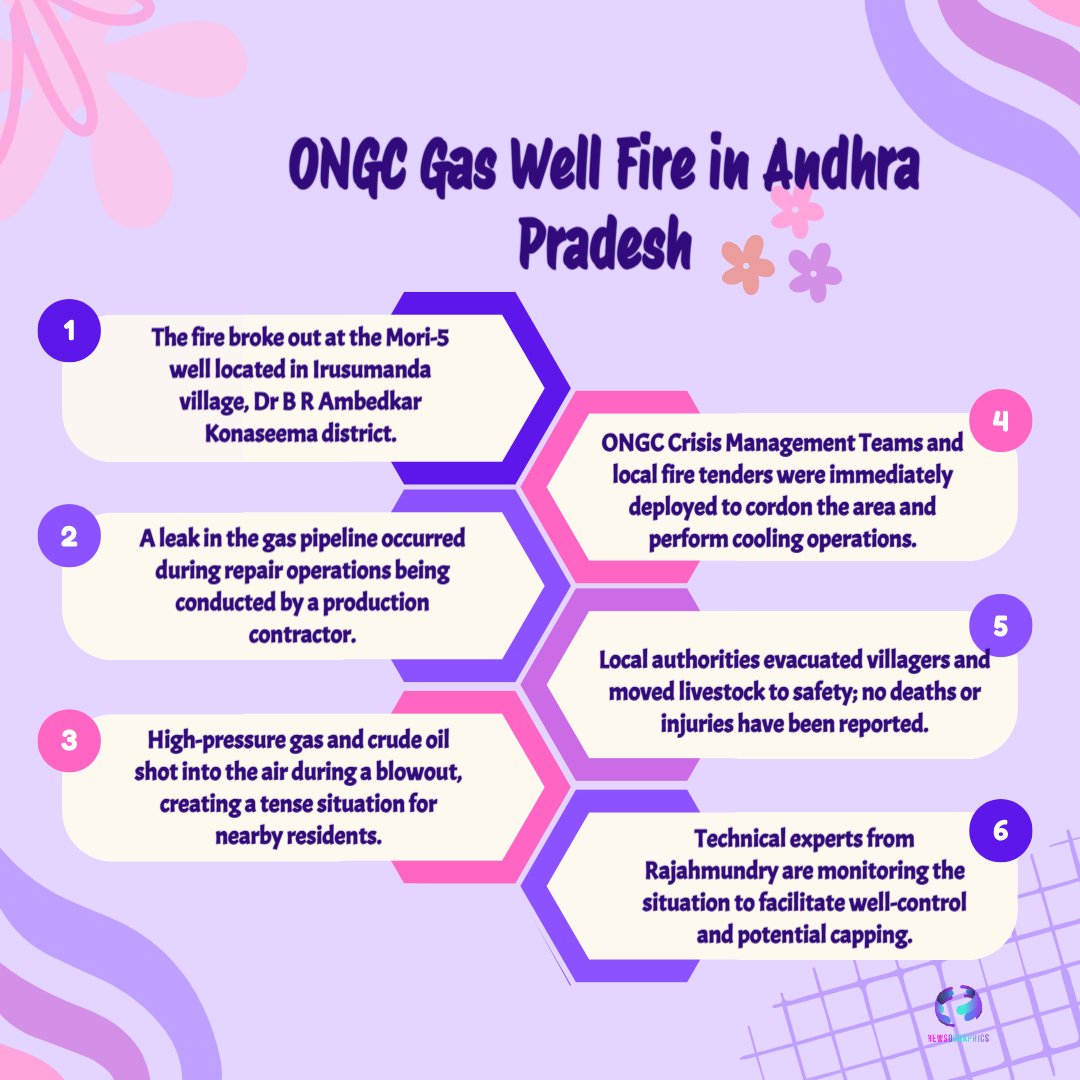

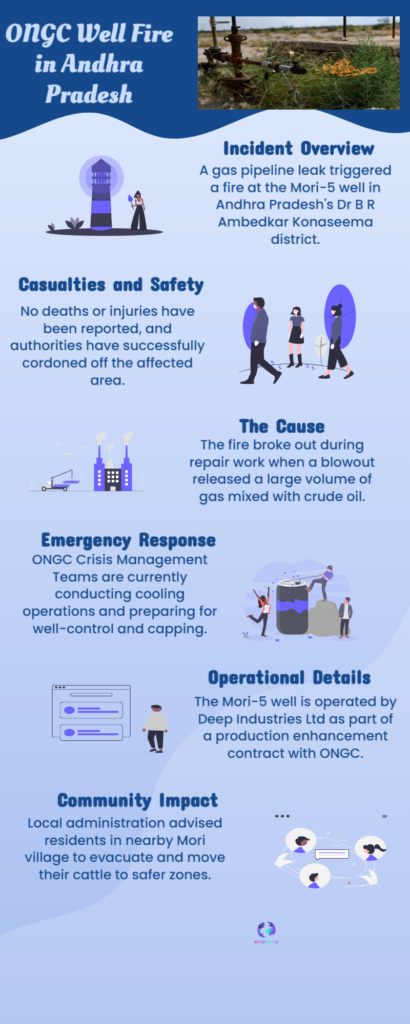

A gas pipeline leak at an ONGC well in Andhra Pradesh’s Konaseema triggered a major fire, spotlighting industrial safety, emergency response, and energy infrastructure risks.

The Incident That Shook Konaseema

A sudden gas pipeline leak at an operational well of Oil and Natural Gas Corporation escalated into a fire in Andhra Pradesh Konaseema region, sending shockwaves through nearby communities and the energy sector. The blaze, visible from a distance, underscored how rapidly routine industrial operations can turn hazardous when pressurised gas systems fail.

Andhra Pradesh’s Konaseema, known more for its agrarian landscape than industrial emergencies, found itself at the centre of a high-risk event that demanded swift containment and coordination. The incident highlighted the delicate balance between energy extraction and local safety in densely inhabited regions.

Anatomy of a Gas Pipeline Leak

Pressure, Material Stress, and Ignition

Gas pipelines operate under sustained pressure, transporting volatile hydrocarbons across long distances. Even minor material fatigue, corrosion, or valve malfunction can release gas into the open. Once exposed, a single ignition source—static discharge, mechanical friction, or ambient heat—can trigger combustion within seconds.

Why Fires Escalate So Quickly

Unlike liquid spills, gas disperses invisibly and rapidly. In confined or semi-open spaces around wells, accumulation increases the probability of ignition, explaining why such incidents often transition from leak to fire almost instantaneously.

Emergency Response and Containment

Coordinated Firefighting Efforts

Fire and safety teams moved to isolate the affected section of the pipeline, focusing on cutting off gas flow to starve the flames. Water curtains and controlled cooling were deployed to prevent heat from compromising adjacent infrastructure.

Evacuation and Local Safeguards

As a precaution, nearby areas were secured to minimise civilian exposure. The response reflected established industrial disaster protocols, designed to prioritise human safety before asset recovery.

Impact on Energy Operations

Temporary Disruption, Broader Implications

While immediate production from the affected well was halted, the broader concern lies in operational continuity across similar assets. Incidents like this compel energy operators to reassess inspection cycles, maintenance rigor, and real-time monitoring systems.

Reputational and Regulatory Pressure

For ONGC, India’s flagship upstream energy producer, such events intensify scrutiny from regulators and the public alike. Safety lapses—perceived or real—carry reputational costs that extend beyond the incident site.

Industrial Safety in High-Density Regions

Konaseema’s Unique Vulnerability

The Andhra Pradesh Konaseema belt combines wetlands, villages, and critical infrastructure in close proximity. Industrial activity here magnifies risk exposure, making robust safety buffers and community awareness essential components of operations.

Lessons for the Energy Sector

This fire reinforces the need for predictive maintenance, advanced leak-detection technologies, and strict adherence to safety audits. In regions where livelihoods and infrastructure intersect, prevention becomes as crucial as response.

A Broader Reflection on Infrastructure Risk

Gas pipeline fires are not isolated anomalies but reminders of systemic vulnerability within aging and expanding energy networks. As India balances energy demand with safety imperatives, incidents in places like Andhra Pradesh Konaseema serve as inflection points—forcing renewed attention on how infrastructure is built, monitored, and safeguarded.

The Andhra Pradesh Konaseema fire, though contained, leaves behind a clear message: in the energy economy, vigilance is not optional—it is foundational.